An international transportation company with annual revenue of $2 billion had a problem on April 28.

One of its trucks had suffered a spill of resin on its trailer and outside of the trailer in Bensenville, IL.

The spill site was less than 12 miles from HazChem’s home base in Addison, IL.

The call for emergency-response help to HazChem came in at 12:45 p.m.

“We were also told that some of the resin may have entered a sewer,” said HazChem Co-Owner Chris Johnson.

A three-man HazChem crew loaded up an emergency truck with supplies and equipment, most significantly a drum vacuum.

“That drum vacuum could start sucking out resin from the sewer,” Johnson explained. “Our crew knew to inspect that sewer the second they arrived at the spill site. If the sewer was heavily impacted, we were ready to send a vacuum truck.

“If we were able to avoid sending a vacuum truck that would mean less cost to our client. We always know that’s appreciated.”

The crew arrived on-site at 1:22 p.m.

“Our crew manager called me and told me the drum vacuum would be sufficient in pulling up the spillage in the sewer,” Johnson said. “Thankfully, only a small amount of resin had leaked into the sewer. We sucked it up immediately.”

The crew then needed to clean a messy trailer and the spillage outside.

Oil dry was used inside the trailer. The crew used a pallet jack to move freight.

“Our crew needed to get to the source of this spill, a damaged drum, and that drum was toward the nose of the trailer,” Johnson explained.

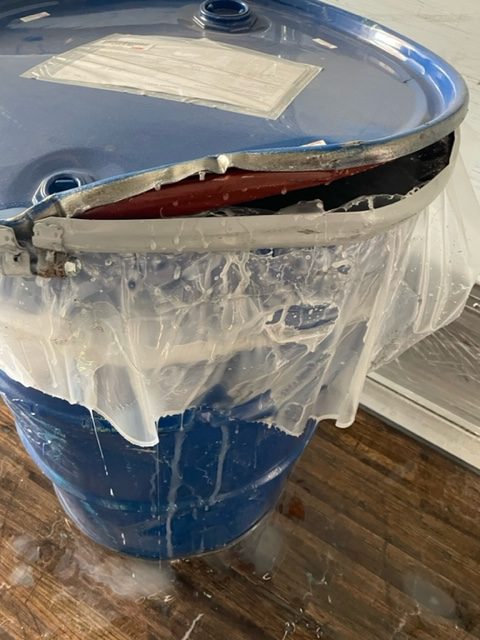

The leaking drum was smashed at its top.

“Our crew laid down the proper amount of oil dry to allow themselves to gain the proper traction to handle an over-pack,” Johnson said.

The crew was ultimately successful in putting the damaged 55-gallon drum into an 85-gallon open-top-steel drum.

All the pallets on the trailer were contaminated. So the crew placed all the remaining freight onto new pallets that HazChem had brought to the site.

Oil dry continued to be the most effective consumable in the cleaning of this spill.

“Our crew kept working in the oil dry and then putting that worked-in oil dry into drums of waste,” Johnson said. “Since the damaged drum had a full release of 55 gallons, this resin was spread out quite a bit.

“Eventually the inside of the trailer was cleaned. Then our crew cleaned the outside part of this spillage, again employing the oil dry. There was also some resin on the outside walls of the trailer so our crew used universal pads to wipe that resin off.”

Ultimately, the HazChem crew used five drums to hold the worked-in oil dry, used pads, PPE and scraped-up resin. In total, the HazChem crew was on-site for two hours, 45 minutes.

“Considering how widespread this spill was, that’s a quick time period to have finished up in,” Johnson said. “And our client called us and said, ‘Thank you for doing an excellent job for us.’

“When our clients are happy, we’re happy.”

Recent Comments