Preparation is the key to being a solid hazmat-trained technician.

“It may sound a little simplistic,” says HazChem Environmental Co-Owner Alan Shapiro, “but being prepared is the key to the success we’ve had over the past 32 years.”

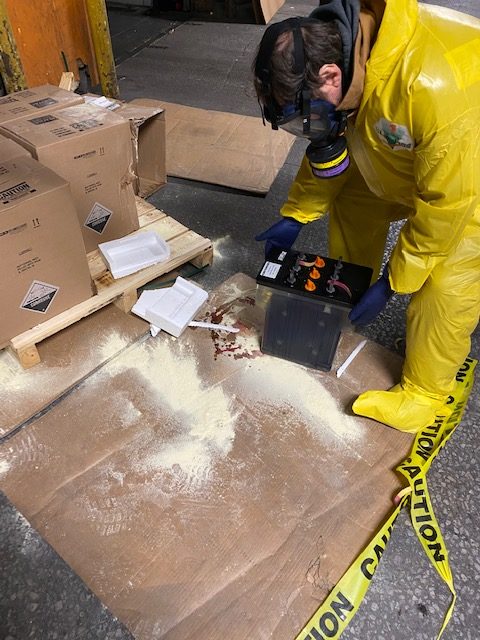

On December 29, at 3:05 a.m., HazChem was called for an emergency cleanup spill involving battery acid.

While spilled battery acid is a serious issue, this type of cleanup spill is relatively routine for HazChem.

The call had come from one of the largest freight-carrying companies in America and a longtime client of HazChem’s.

“Once our crew arrived, they followed our usual procedures for handling spilled battery acid,” Shapiro explained.

The crew donned Level “C” Tyvec Suits with Air Purifying Respirators. On the dock at the terminal, the crew began dealing with the six batteries which were leaking acid.

“We neutralized this spill using a combination of Sodium Bicarbonate and water,” said F.Y., the HazChem crew manager.

Once neutralized, each battery was carefully placed into a 55-gallon drum.

Due to the spill on the dock and trailer floor, the crew needed to pick up the water and sodium bicarbonate and did so with oil dry.

The crew then put all worked-in oil dry into a drum containing other waste, including used Universal Pads.

A number of the pallets on the trailer were also contaminated and so each affected pallet was neutralized.

“The bottom line,” Shapiro said, “is that we must make sure the trailer and the dock are completely cleaned of the acid — and this crew did exactly that.”

Once this spill was cleaned up, the crew did its final inspection of the entire trailer.

“At the nose of the trailer, we saw some liquid leaking and noticed a damaged 5-gallon pail,” F.Y. said. “This was a completely different spill than the one we had just cleaned up.

“That doesn’t happen often but, from time to time, we see something like this — a different spill of a different product in an entirely different area of the trailer.”

F.Y. then notified the dock supervisor of the second issue. By this time, with the battery acid completely neutralized, it was safe for the freight company employee to enter the trailer.

“The dock supervisor then called her own immediate supervisor,” F.Y. said. “And then, a few minutes later, I was asked to clean up this second spill.

“Our customer was hoping that we’d have enough time to clean up the spill immediately and they were also hoping we had enough supplies to clean up the spill immediately. If not, they wanted to see if we could come back later and handle this.

“We were prepared. We had extra supplies on our emergency-response truck and told our customer we would handle cleaning up this second spill immediately.”

All told, the crew found nine 5-gallon pails, each containing soil amendment, which were damaged. The HazChem crew pulled out from its truck two new 55-gallon drums, extra drums brought for the trip, and used it to hold the damaged pails.

This particular soil amendment was not hazardous and the cleanup went smoothly.

“We used oil dry, pads, brooms and shovels and had the entire second spill cleaned up in 30 minutes,” F.Y said. “We always try and pack extra drums for every spill we go to, just in case we need it. This time we needed it — it was good we were prepared.”

Recent Comments