Emergency Mercury Spill Remediation

HazChem received a frantic call requesting an emergency mercury spill remediation. Apparently a large bulb and other mercury-containing devices had broken inside a supply closet. Nearly a pound of hazardous mercury was spilt. The HazChem Emergency Rapid Response Team arrived on site and immediately conducted air monitoring within the supply closet to begin the mercury remediation in Chicago, IL. The contamination was found to be isolated to the entire supply closet, but fortunately was not tracked outside. Due to the building being considered historic, HazChem needed to be careful with the remediation process and not cause any damage to non-contaminated areas. Since the hardwood floors and wooden shelving were not sealed, mercury was absorbed into the wood.

To remediate, all chemicals in the supply closet needed to be lab packed. All other items that were considered low value were disposed of, and all high value items were vapor head space sampled. Once all the items in the supply closet were removed, the crew conducted mercury vacuum operations in the area where the mercury had been released. After all visible mercury was collected, the crew broke down the shelves and placed them into cubic yard boxes for disposal. Due to the wood and concrete walls absorbing the mercury, the triple rinse wash method was used. However, it was not effective at remediating all of the mercury. Therefore, an epoxy seal was used for the floor and walls. Once the room passed inspection with the mercury monitor, the job was complete. HazChem specializes in Mercury Remediation and Mercury Spill Cleanup Services. Our Operations Director, Mark Parquette, is recognized as one of the premier mercury spill cleanup experts in the country.

A broken bulb, and other mercury-containing devices were located.

The chemicals were lab-packed.

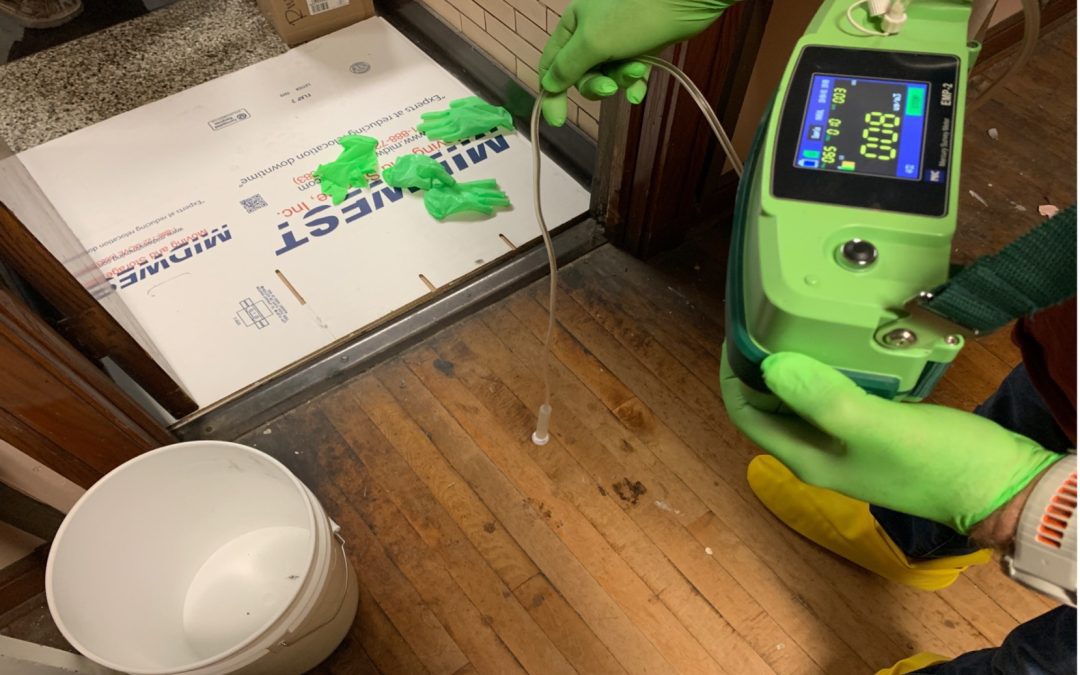

Mercury screening was completed in multiple locations. Mercury vapor head sampling was conducted.

Donned in Level C PPE, a crew member vacuumed visible mercury from the shelf.

Poly sheeting was placed outside of the room and was used as a temporary storage area, as a second crew removed all items from another room. All items that were not considered “high value” were bagged before being disposed of in the roll off box. Larger items were disassembled before being diposed of. High value items such as microscopes were sealed in a poly bag and heated for a minimum of 15-minutes before mercury vapor headspace sampling was conducted. No reading was above 1 ug/m3.

Poly sheeting was placed outside of the room and was used as a temporary storage area, as a second crew removed all items from another room. All items that were not considered “high value” were bagged before being disposed of in the roll off box. Larger items were disassembled before being diposed of. High value items such as microscopes were sealed in a poly bag and heated for a minimum of 15-minutes before mercury vapor headspace sampling was conducted. No reading was above 1 ug/m3.

All chemicals were removed from the room. A powder that was previously spilt in a box was also discovered. A crew member donned level C PPE to safely collect the powder. The spilt powder and contaminated items were placed and sealed in a 5-gallon poly bucket.

All the chemicals were lab packed into separate waste streams. The crew donned level C PPE and conducted mercury vacuuming in the areas where mercury-containing devices were located. Hazchem technicians removed the shelving from the non-mercury impacted areas first, followed by shelving that held the mercury-containing devices.

The crew donned level C PPE and mercury vacuumed the floor. The crew donned level D Modified PPE and conducted triple rinse washing activities on the mercury impacted walls. Crew members sprayed a mercury soap solution on the walls. A brush was used to agitate the mercury soap solution. A HEPA vacuum was used to collect the mercury soap solution, and then conducted a triple rinse wash method on the floor.

Mercury vapor head space sampling was conducted on the floor after the previous shift conducted their triple rinse washing activities. Vapor head space readings were very high, 118 ug/m3 , at the west wall where the spill initially occurred.

The crew applied painters’ tape to the floor molding and began painting the exposed concrete walls with an epoxy-based paint. After the first coat of epoxy paint was applied to the wall, the crew applied an epoxy paint to the floor. Mercury floor screening was conducted. Test results were 4 ug/m3. Another coat of paint was applied to the walls and floor. Mercury floor screening was conducted in the room again and results were 1 ug/m3. The room passed inspection. HazChem’s crew removed the decontamination zone and moved all equipment and supplies back onto the trucks. All waste was loaded onto a box truck to be transported off-site.

Hallway after HazChem crew succesfully completed the mercury remediation in Chicago.

HazChem Prioritizes Prompt & Effective Emergency Response for Mercury Spill Emergency Remediation and Cleanup:

Emergency spills present significant environmental and public health hazards, emphasizing the importance of prompt and effective response measures to contain the hazardous material spills, mitigate its impacts, and prevent further contamination of soil, water, and air. Learn more about mercury spill cleanup.

HazChem will keep you in compliance with the regulations and help protect you from further liability. With over 30 years in the waste management business, we are trustworthy, safe, reliable, and compliant. Learn more about HazChem Emergency Rapid Response, Chemical Spill Response Services, and Non-Hazardous Waste Disposal.

SUPER-FAST 60-Minute Response Time for Mercury Spills

We understand the urgent and critical nature of your call for service. Our Emergency Rapid Response Teams are ready, willing, and able to respond quickly to remedy your emergency spill situation. Our Emergency Response Vehicles are pre-loaded with 90% of the equipment needed for any emergency situation. The final 10% will be added for your particular needs. This advance preparation enables us to deploy a Team within 60 minutes or less from our facility.

Based upon our clients’ feedback, this is far better than the typical response time from most of our competitors. Their response is usually measured in multiple hours, and sometimes days or even weeks. Our Team is always ready to deploy, 24 hours a day, 365 days per year, rain or shine, including holidays. We do not rely on automated answering systems for our main phone line (630) 458-1910. Instead, we guarantee that a live person will answer your call, regardless of whether it is a weekend, holiday, or any other day.

Compliant. Responsive. Safe.

Call 630-458-1910 for immediate assistance. Open 24/7/365

For a FREE, no-obligation quote, click the button below